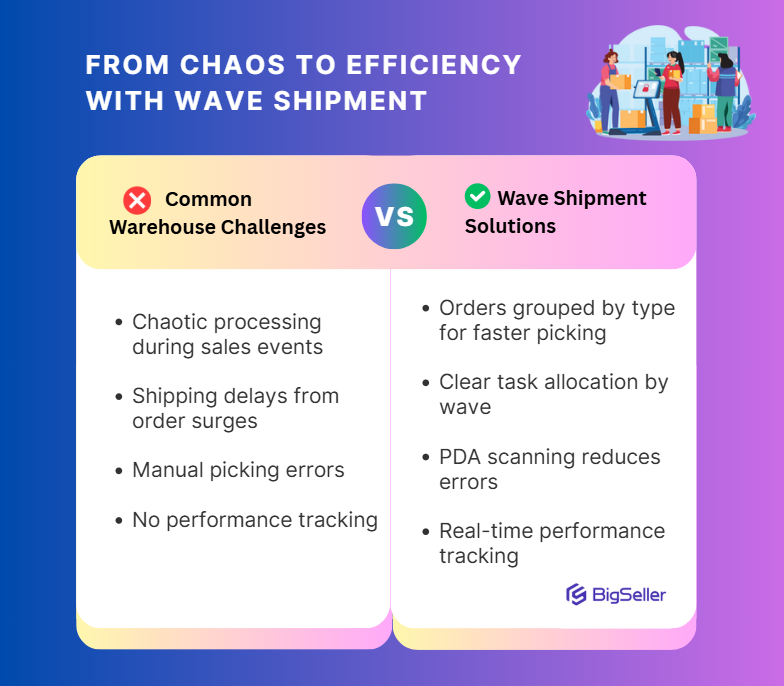

1. What is Wave?

- Instead of processing each order individually, wave operations optimize warehouse workflows by reducing repetitive movement, minimizing human error, and improving processing speed, especially useful during peak sales periods or for high-order-volume warehouses.

- BigSeller also supports task assignment, flexible picking methods, PDA scanning, and performance tracking to help sellers improve operation productivity.

💡 It is recommended that users with a daily order volume of over 300 enable the Wave feature. If you would like to use the wave shipment feature, please contact BigSeller customer service. Our specialist will guide you through the process.

2. Preparation before enabling wave shipment

2) Once enabled, the In Process Orders page will change to Shipping, and all operations such as printing shipping labels, pick lists, and shipping must be done through the WMS Module.

3) After enabling Wave Shipment, Auto Tool will be automatically turned off by default and need to be manually re-enabled.

5) All shipping label printing during wave shipment requires the Auto High Speed Printing Plugin. Please install it here.

6) Recommended equipment to improve warehouse operational efficiency

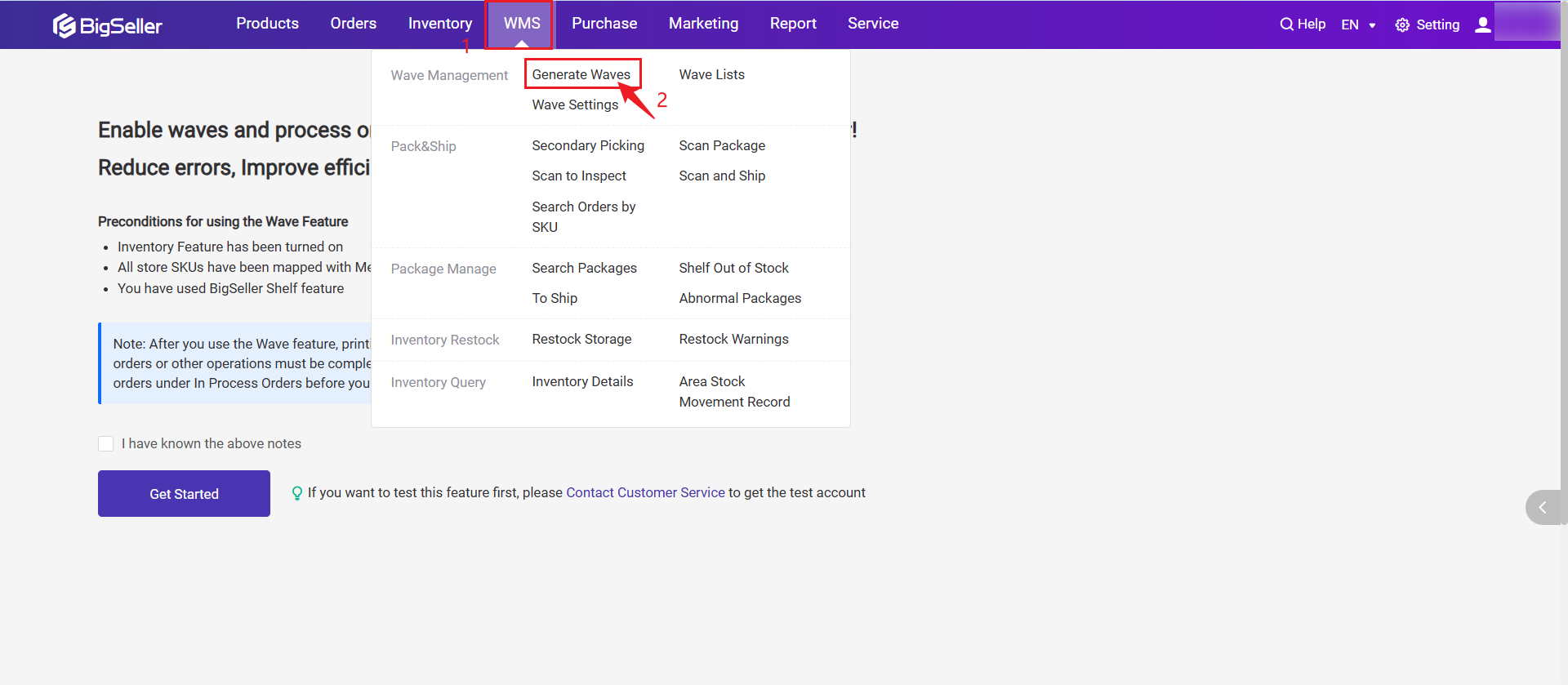

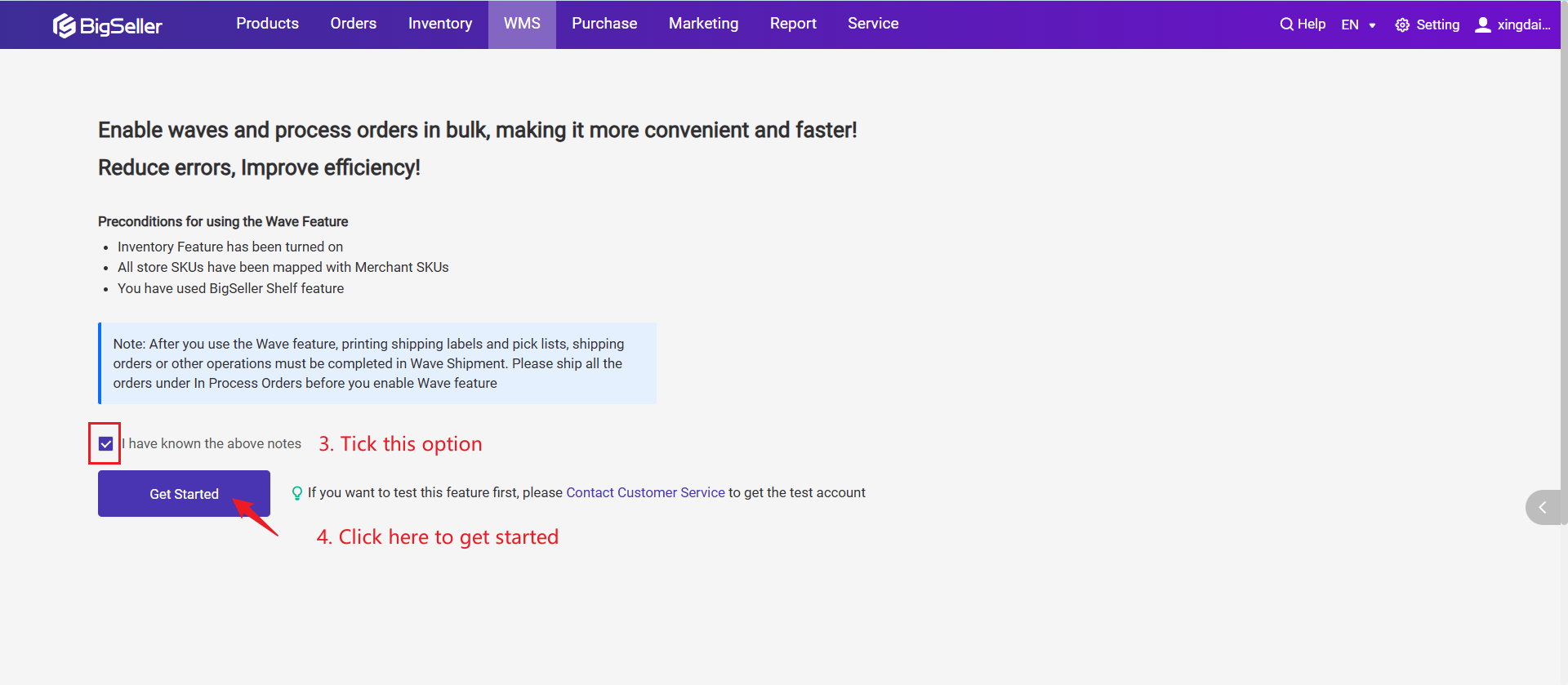

3. How to Turn On / Off Wave?

3.1 Turn On

Go to the [WMS] module > [Generate Waves] page > click Get Started > select the warehouse to enable waves > complete the wave strategy setup.

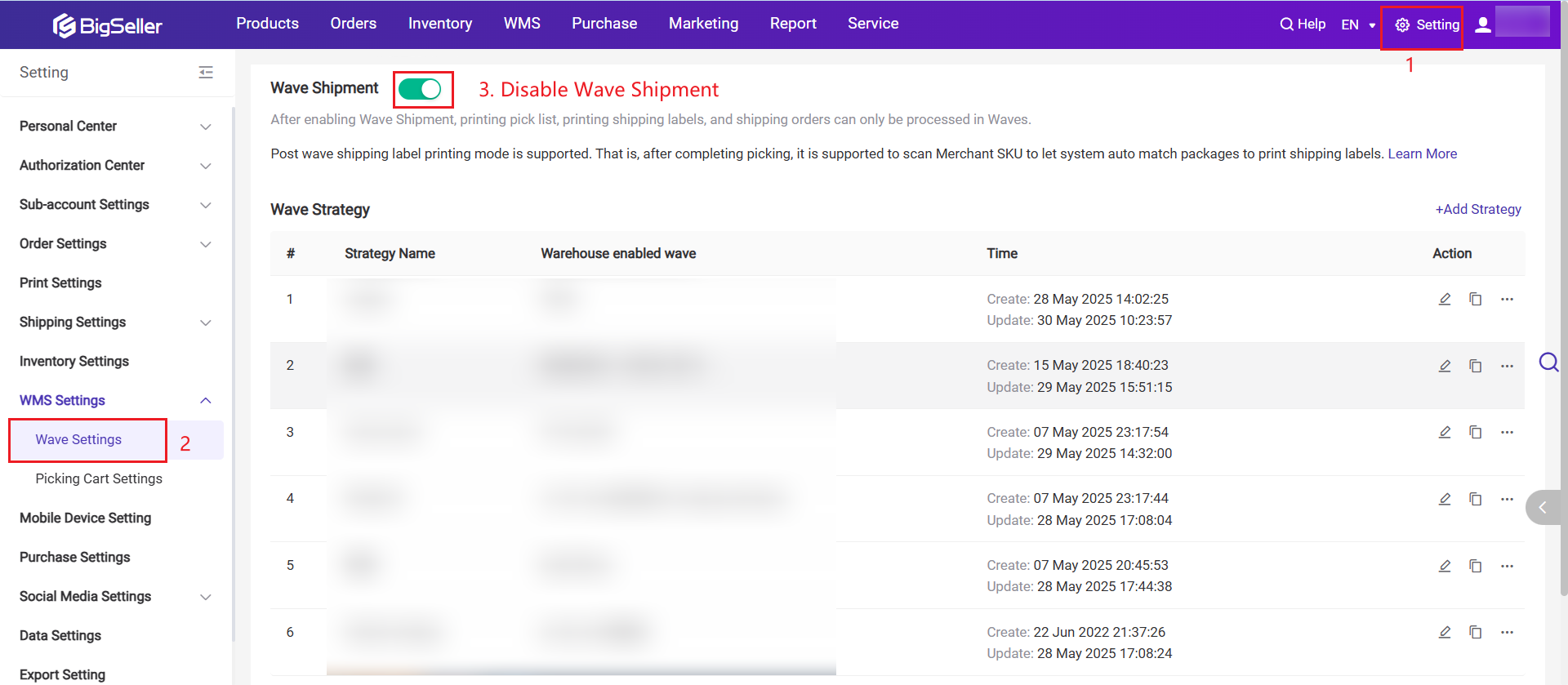

3.2 Turn Off

When disabling the wave feature, the system will check if there are any packages in the 'To Pick', 'To Pack', or 'Packing' statuses. If any exist, an error will be shown and the wave cannot be disabled. All packages must be processed before disabling the wave feature.

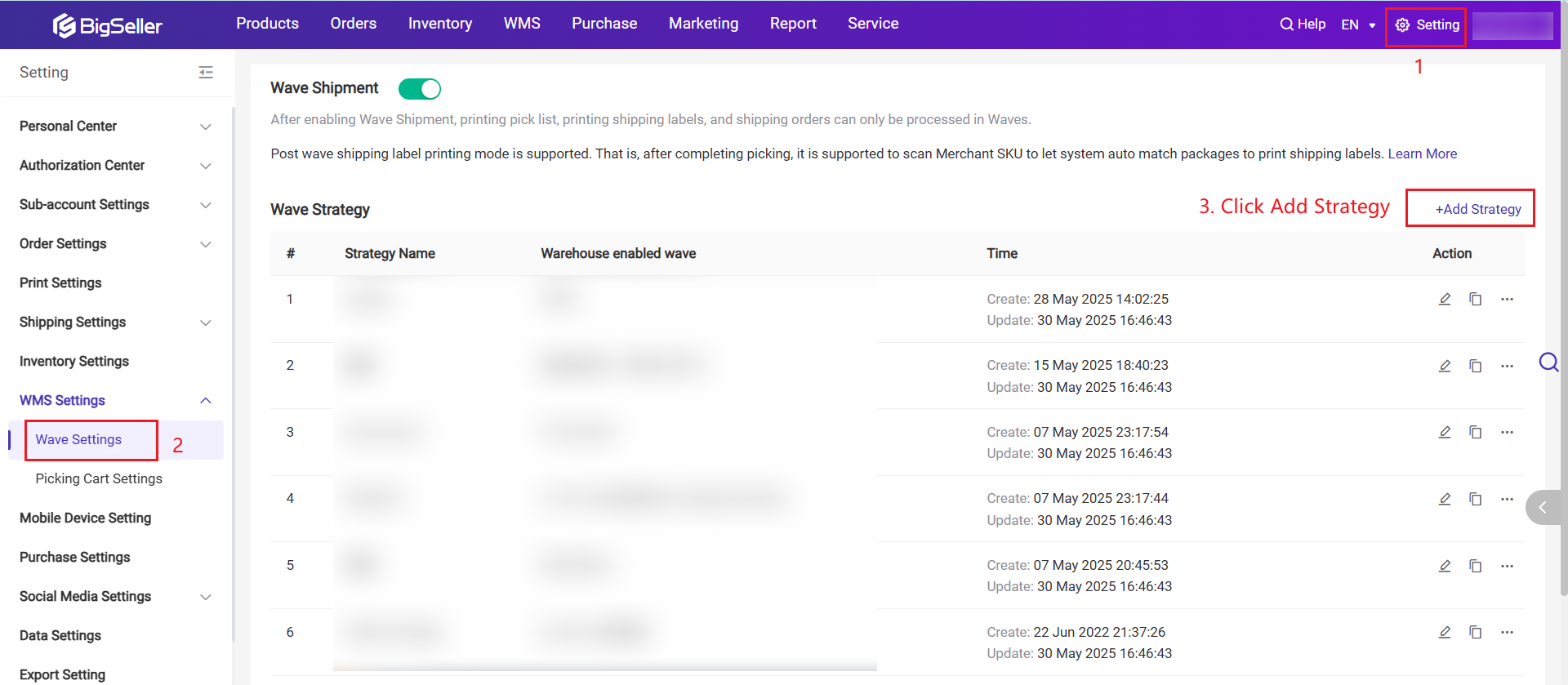

4. Wave Settings

Before using wave shipment, you need to configure wave settings to better align with your business workflow and improve shipping efficiency.

Wave Settings Access: Go to WMS Settings >> Wave Settings page.

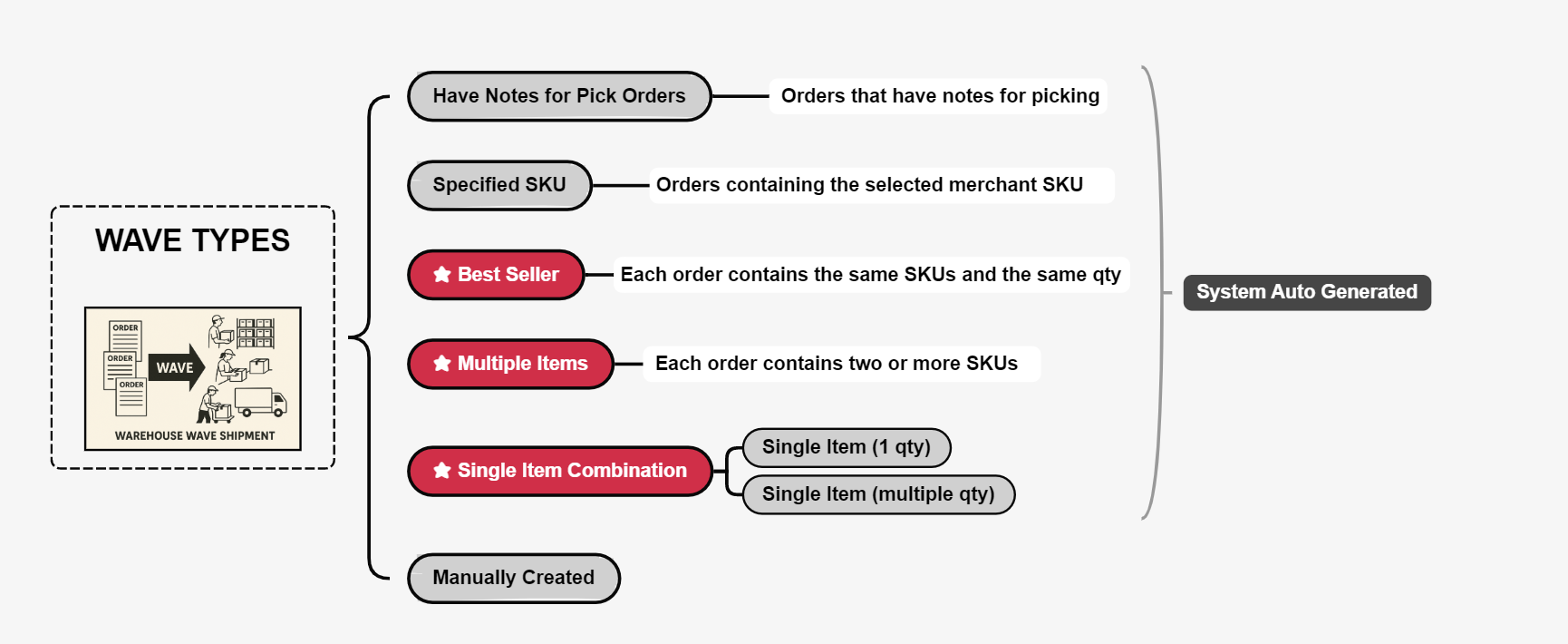

4.1 Wave Type Introduction

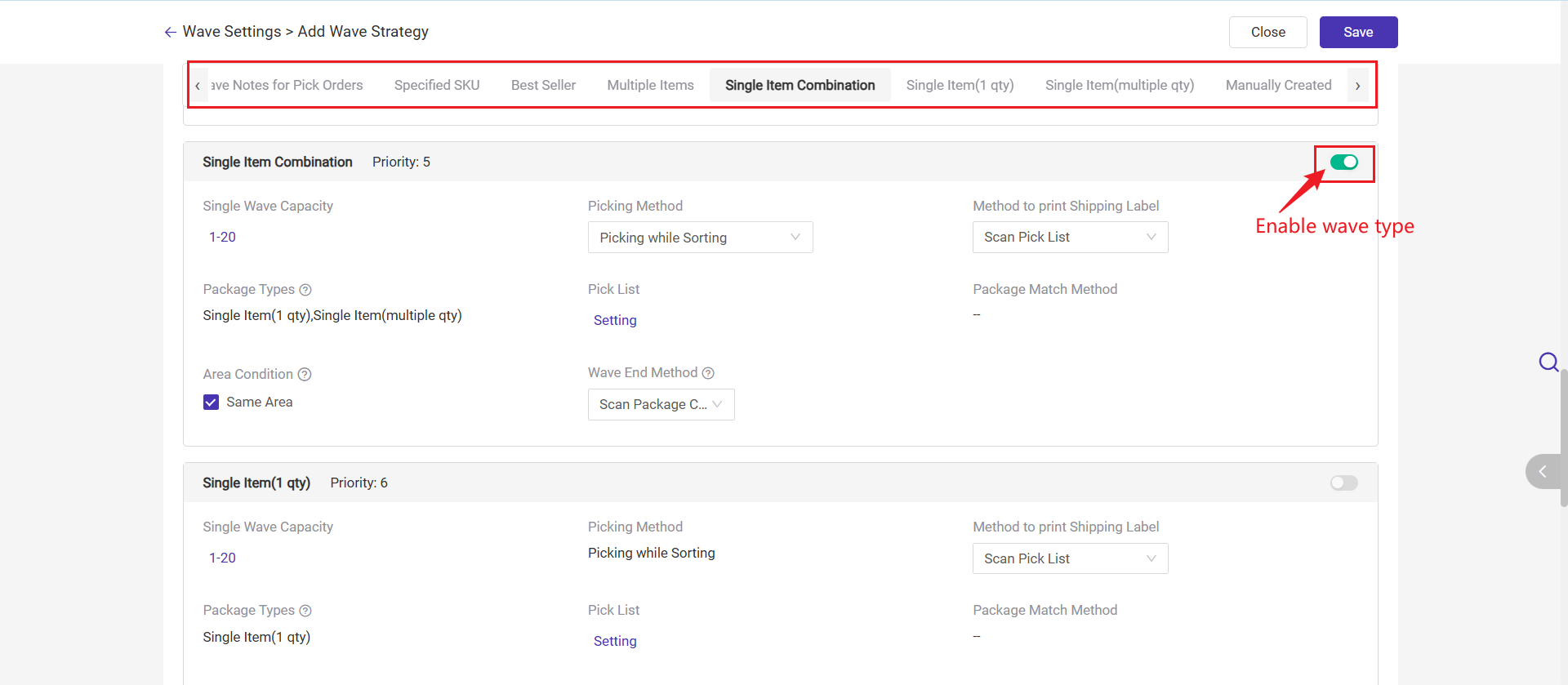

In the Wave Settings, you can customize and enable the wave types according to your actual business needs.

-

Have Notes for Pick Orders

Used for orders that include special picking notes.

This helps warehouse staff handle orders with unique picking requirements in a focused manner. -

Specified SKU (Special Products)

Used for bulky items or products stored in specific warehouse zones.

By categorizing them as special products, these can be picked in batches to improve efficiency. -

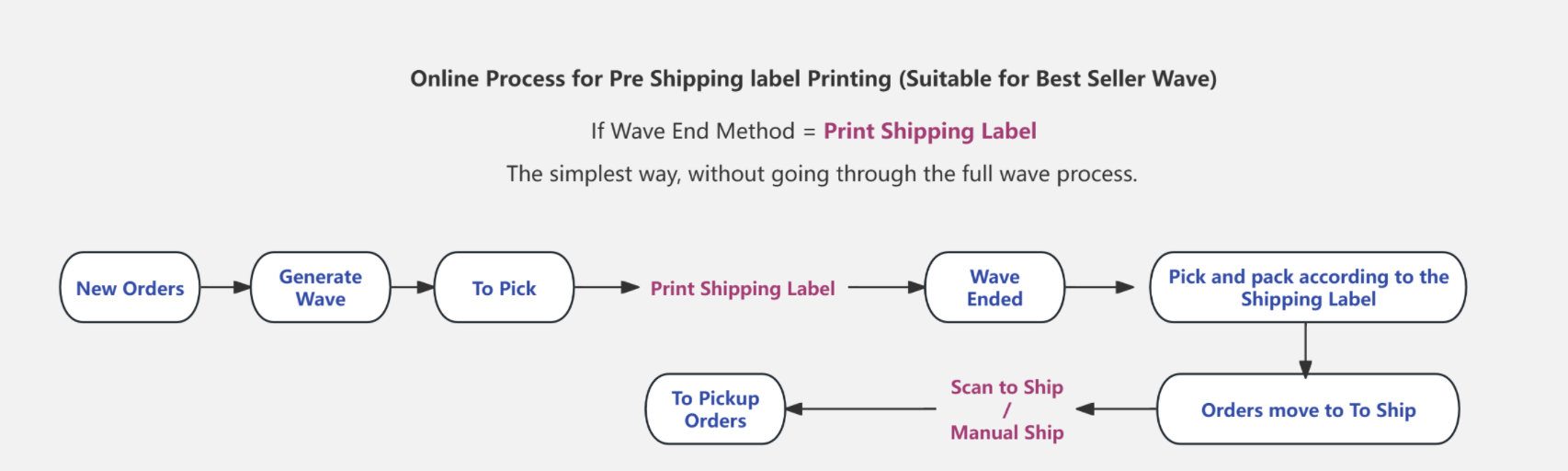

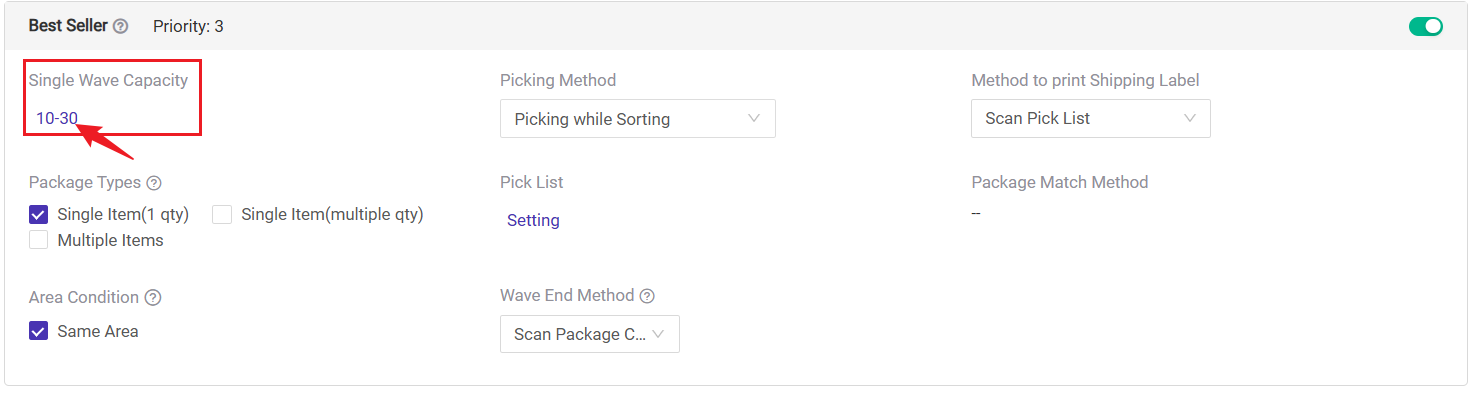

Best Seller Wave

Used in high-demand scenarios like promotions.

The system groups orders with the same SKU and same quantity into a single wave once they reach a defined quantity threshold.

Best Seller Wave Process Recommendations -

Multiple Items (Mixed-SKU Orders)

Used for orders containing two or more SKUs.

Since variety increases the risk of picking errors, it's recommended to process these with more precise picking methods. -

Single Item (1 qty)

Orders with only one SKU and a quantity of 1.

These are simple orders, easy to pick and ideal for batch processing. -

Single Item (multiple qty)

Orders with only one SKU but a quantity of 2 or more.

Although the SKU is the same, the quantity variation requires slightly more attention during picking. -

Single Item Combination

Combines both Single Item (1 qty) and Single Item (multiple qty). -

Manually Created

Used when orders need to be selected manually for wave creation.

Provides flexibility for exceptional cases or custom picking logic.

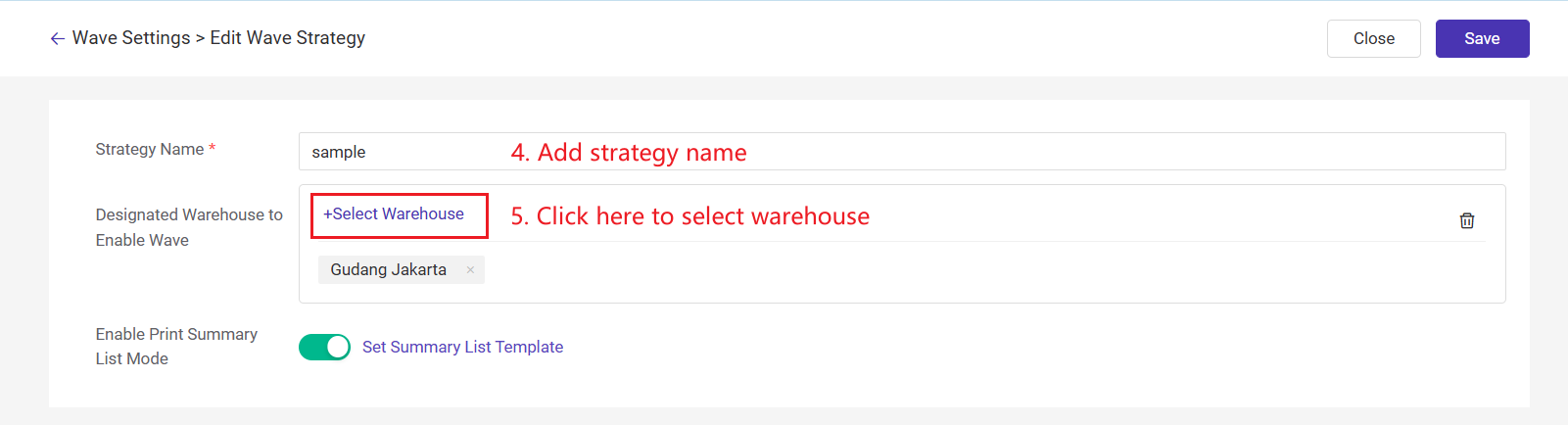

4.2 Wave Strategy Settings

-

You can enable wave shipment by warehouse, so each warehouse can have its own customized wave strategy.

-

Once wave shipment is enabled for a warehouse, all orders in that warehouse will follow the wave processing workflow. Orders from warehouses where wave shipment is not enabled will continue to follow the regular order processing flow.

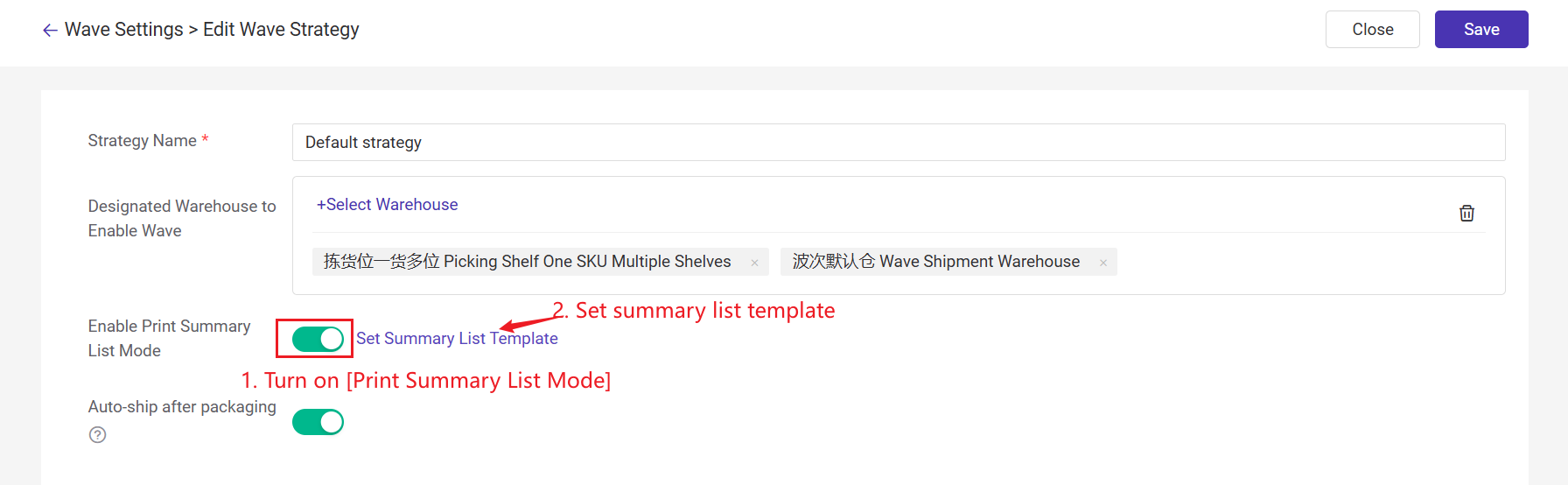

BigSeller supports cross-wave printing of the Summary List and allows setting up a Summary List template. This feature is suitable for the following two scenarios:

-

Summary List Picking + Shipping Label Packing

The picker picks SKUs based on the summary list, and the packer matches items to orders using the shipping labels. -

Summary List Picking + Secondary Picking / Scan Package

The picker picks SKUs based on the summary list, and the packer completes packing in the system via the Secondary Picking or Scan Package page.

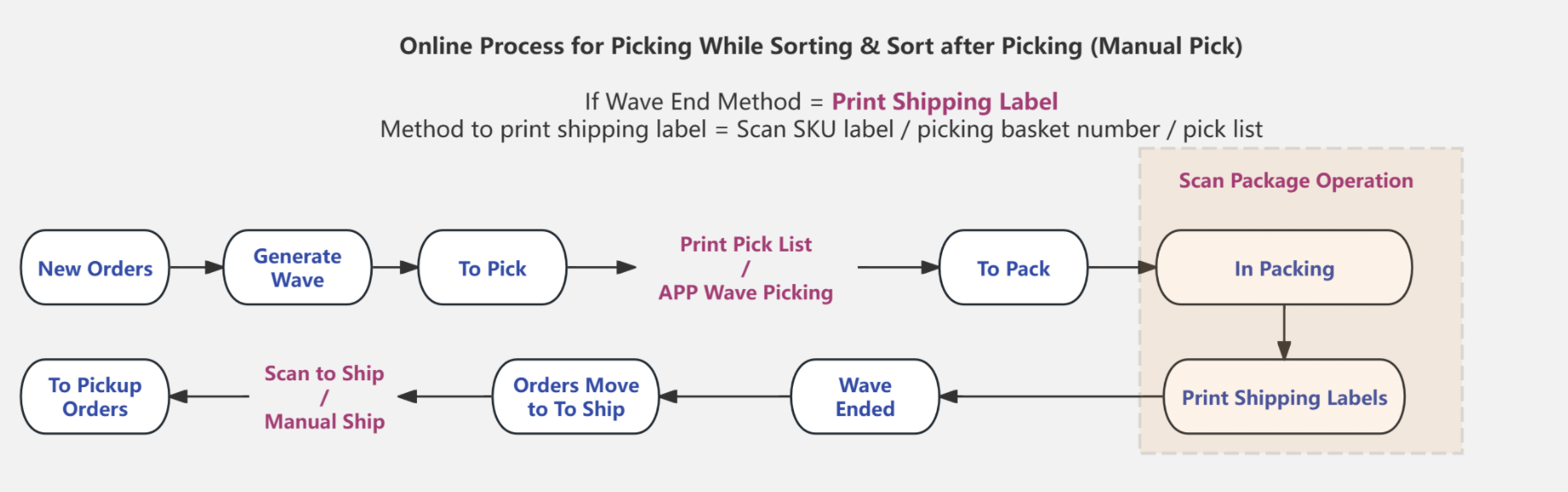

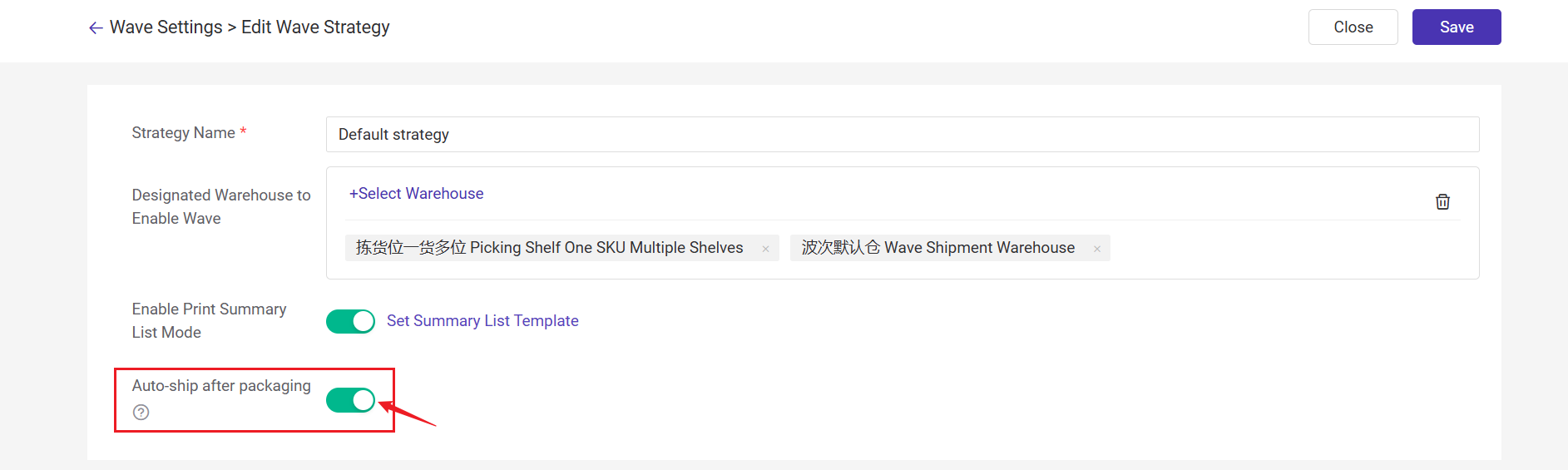

When this feature is enabled, the system will automatically ship orders and deduct inventory right after the scan package operation process is completed. This eliminates repetitive steps and improves warehouse efficiency and data accuracy.

To enable: Go to Wave Setting > turn on Auto Ship After Packaging Completed.

- After the Scan Package process is finished and the shipping label is printed, the package will be automatically moved to the [To Pickup Orders] list.

- You can view real-time data of orders that have completed shipping label printing and packaging in the [To Pickup Orders] list.

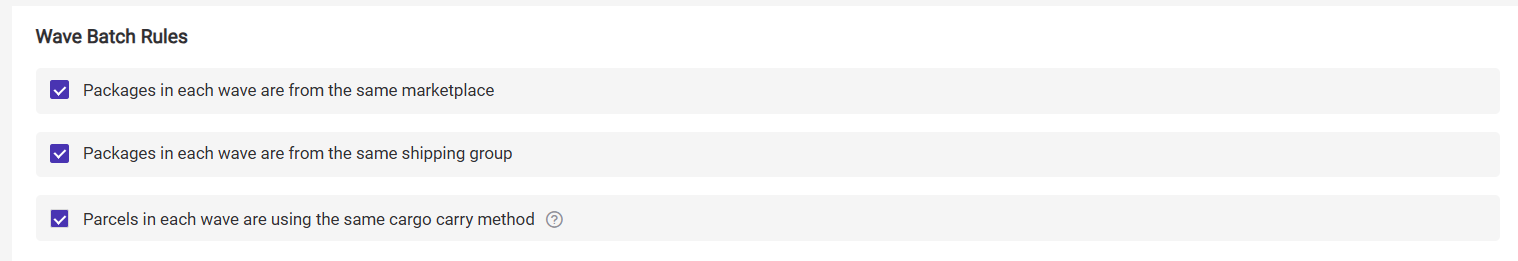

- Packages within each wave must come from the same marketplace.

- Packages within each wave must belong to the same shipping group (e.g., grouped by courier for easier Scan to Ship processing).

- Packages within each wave must use the same delivery method (e.g., Drop-off or Pickup).

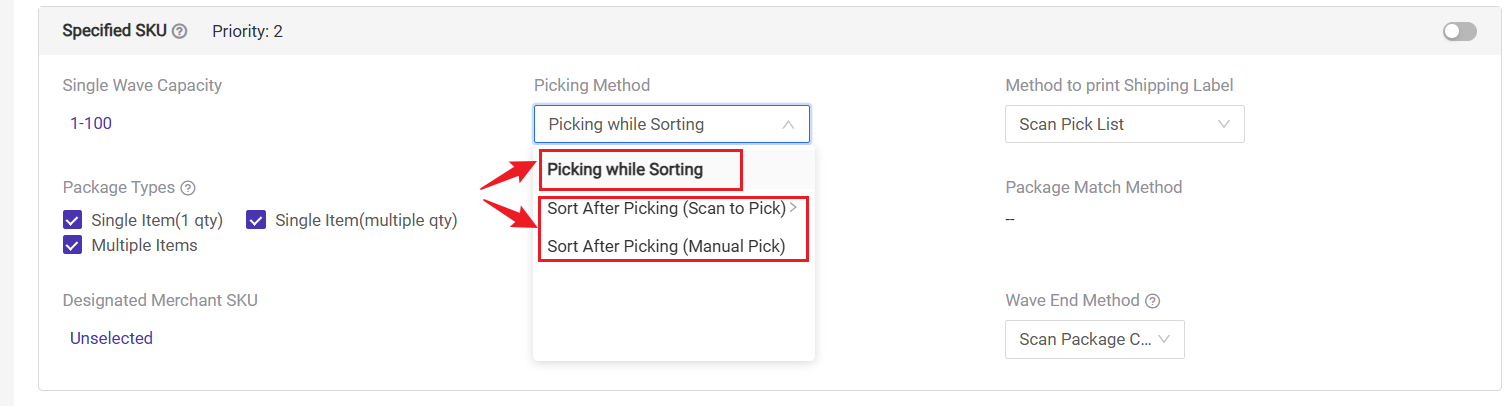

- Used in scenarios where products do not have labels.

- The picker pushes a picking cart and places each item into the corresponding picking basket while picking. One basket corresponds to one package.

-

Manual Pick: Suitable when products have visually distinct appearances or no labels. Sorting and packing are done manually using the pick list or shipping label.

-

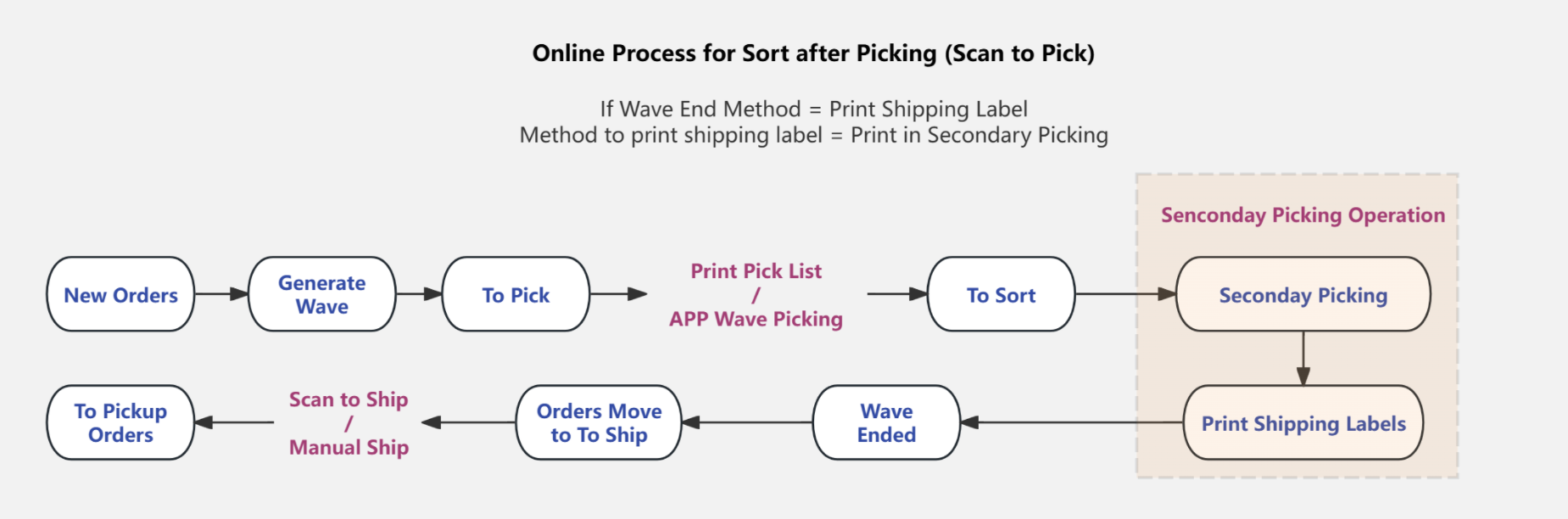

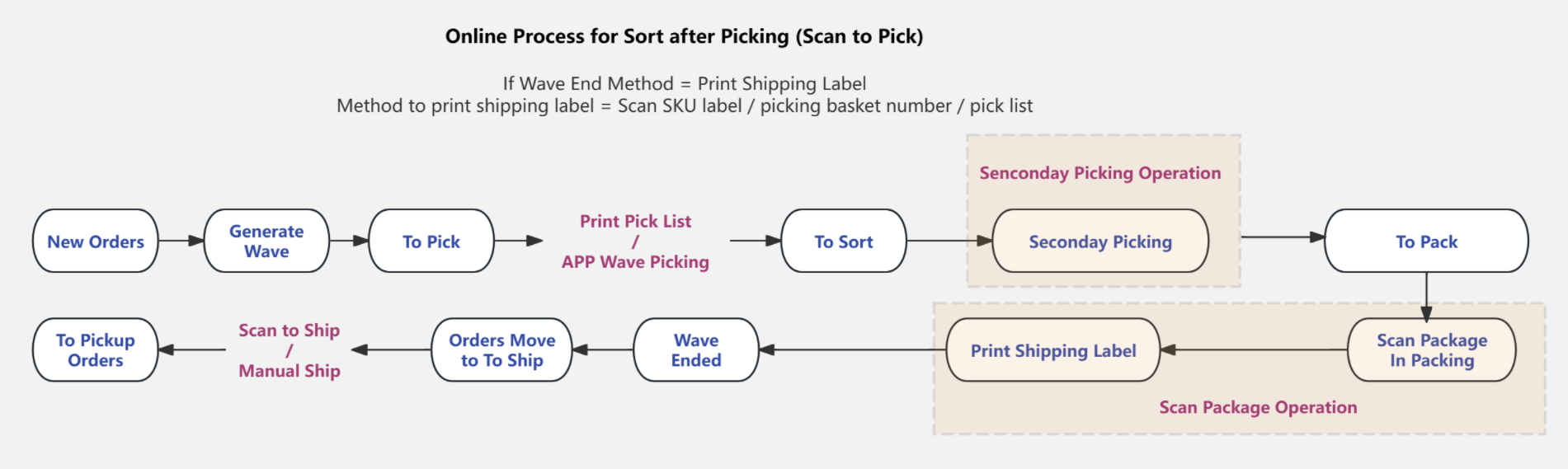

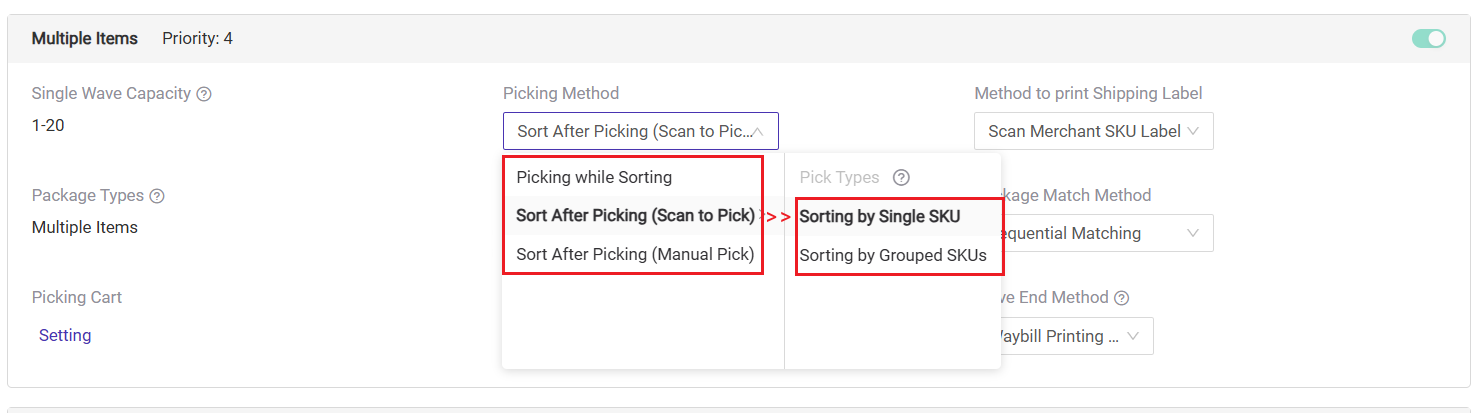

Scan to Pick: requires labeled products and scanning for secondary picking; Two modes available👇:

-

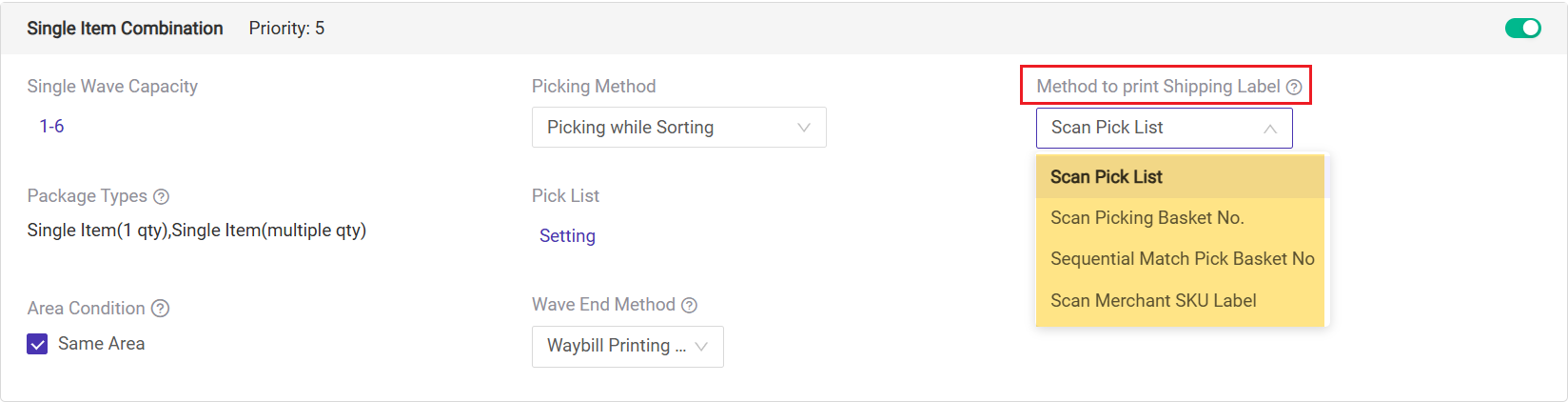

Scan Pick List: Scan the barcode on the picking list to print shipping labels for all parcels in the wave at once.

- Scan Picking Basket Number: Scan the barcode on the picking basket, and the system will automatically print the shipping label for the corresponding package

- Sequential Match Picking Basket Number: No scanning needed — the system auto-matches baskets (1→2→3). Just confirm the package and press Enter to print; the next basket appears automatically.

-

Print in Secondary Picking: Only applicable for the "Sort after Picking - Scan to Pick" wave type. Print the shipping label after completing sorting in the Secondary Picking page.

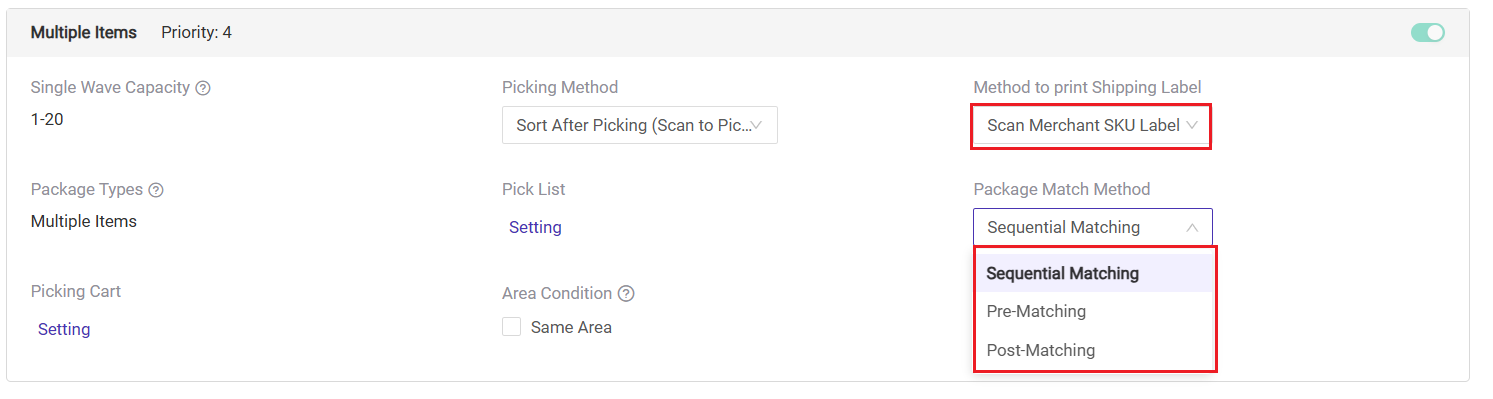

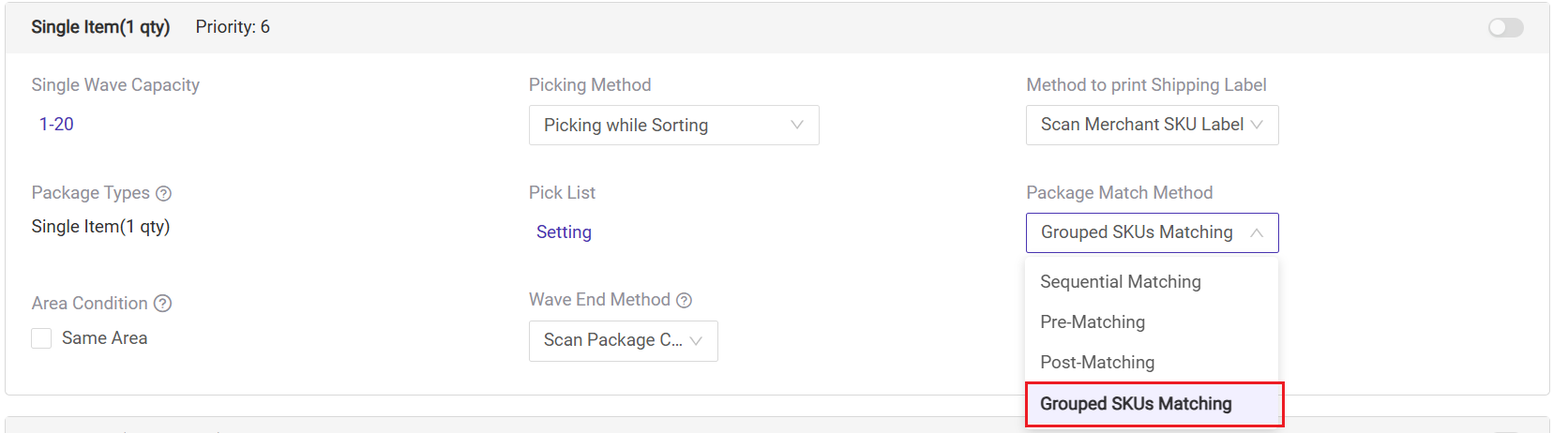

- Scan Merchant SKU Label: Used when products are already labeled. Scan the product label to match the order and print the shipping label.

If choosing "Scan Merchant SKU Label" to print shipping labels, three Package Match Methods are supported:

💌 [New Feature] For Single Item (1 qty) and Best Seller wave types, you can use the Grouped SKU Matching method. By scanning once, you can scan all the same items in the wave without having to scan each quantity individually, reducing scanning steps and making the process more convenient.

For detailed instructions, please refer to Introduction to Grouped SKU Matching for Scan Package

- For wave types like Single Item, Specified SKU, and Best Seller, you can set the maximum number of packages per wave.

- For example, if you set the single wave capacity to 20, the system will automatically split 40 single-item packages into 2 waves, with 20 packages in each wave.

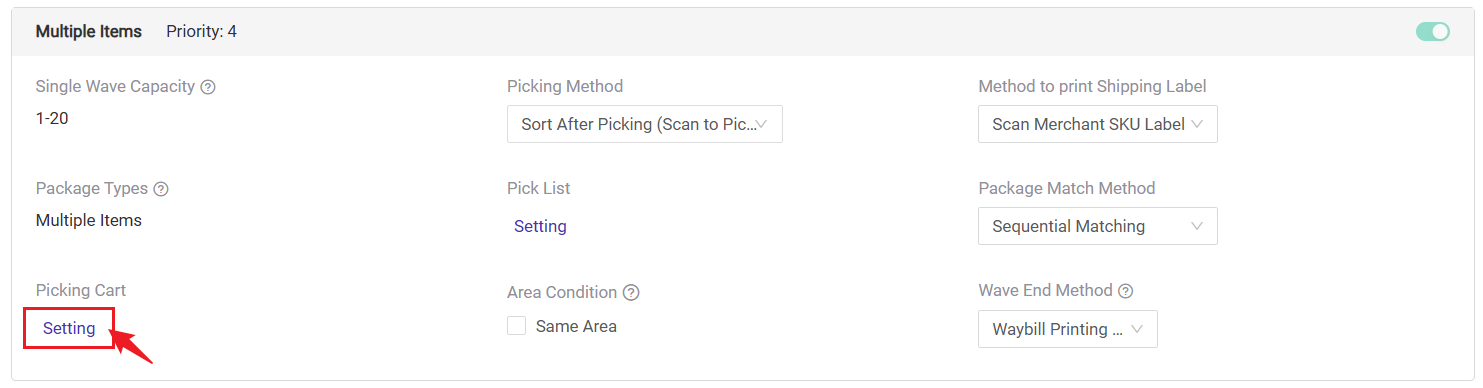

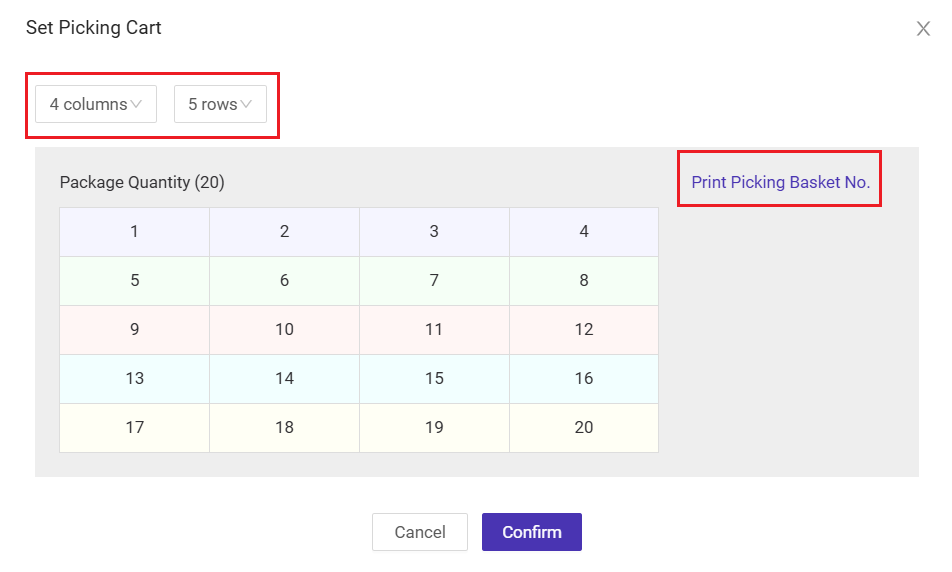

-

Set up wave batches based on the number of rows and columns in the picking cart.

-

You can print picking basket No.

-

Setup path: Go to Multiple Items wave > Click Picking Cart.

-

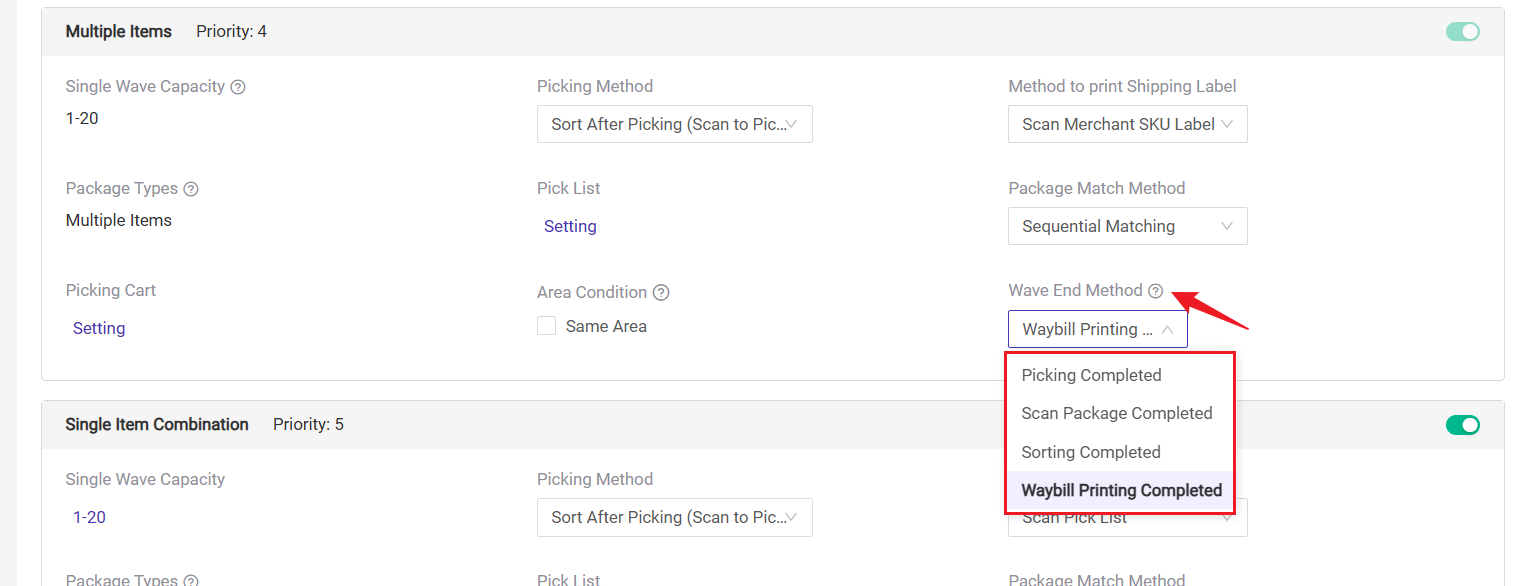

Scan Package Completed: The wave ends after completing the Scan Package process.

-

Picking Completed: The wave ends after confirming the printing of the pick list or summary list on the PC, or after picking is completed on the app.

-

Waybill Printing Completed: The wave ends automatically after all waybills (shipping labels) are printed. Batch printing supports up to 5000 orders at once.

- Sorting Completed:The wave ends after completing the secondary picking operation.

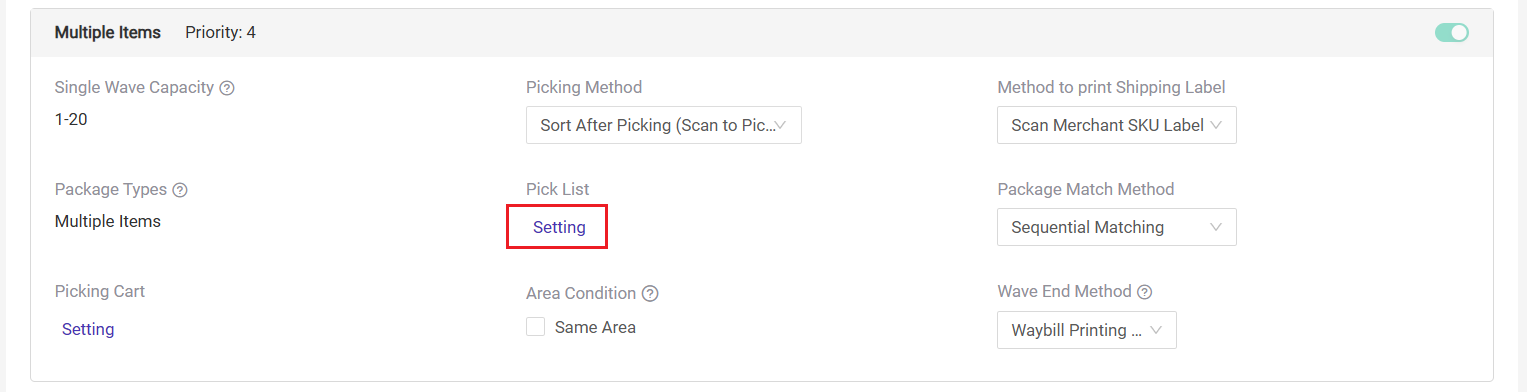

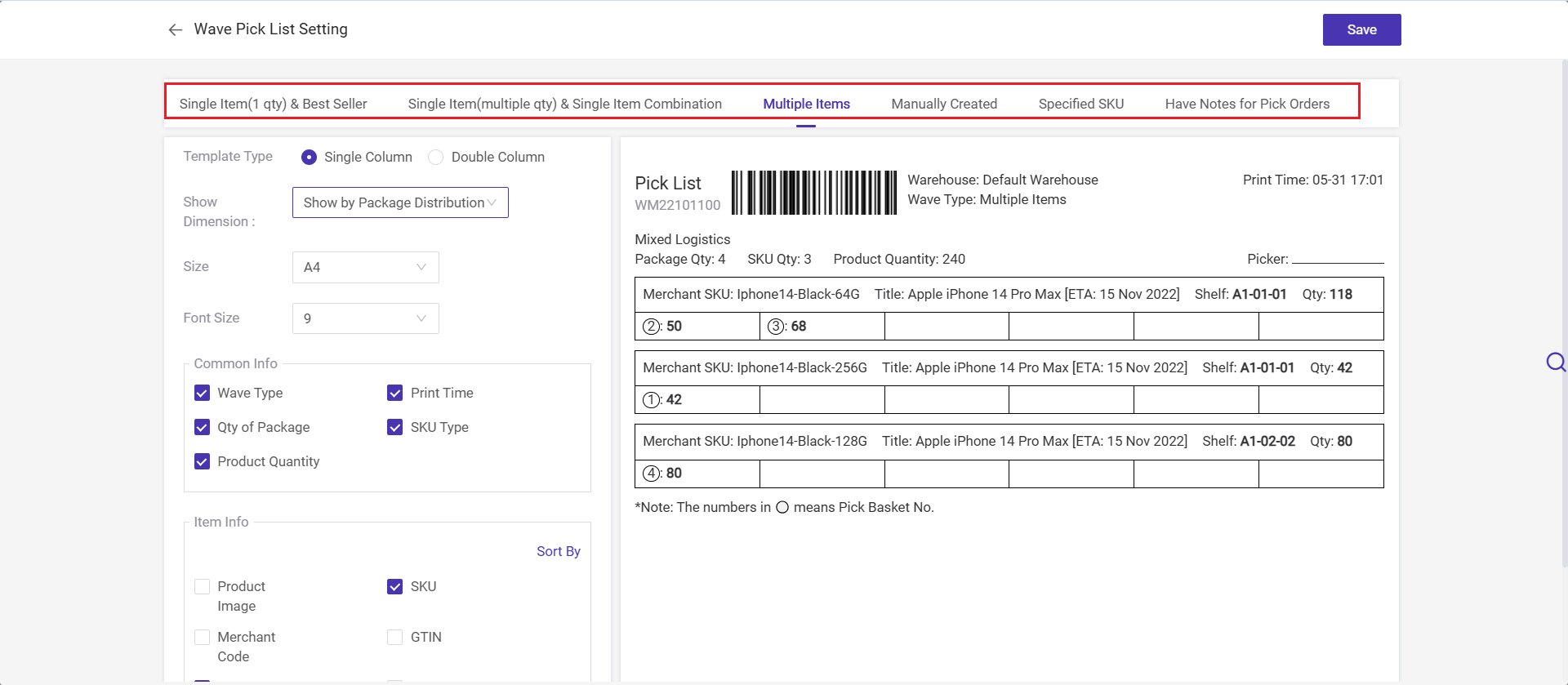

- Supports setting different Pick List templates for each wave type.

- You can directly jump to the corresponding Pick List settings page to configure them.

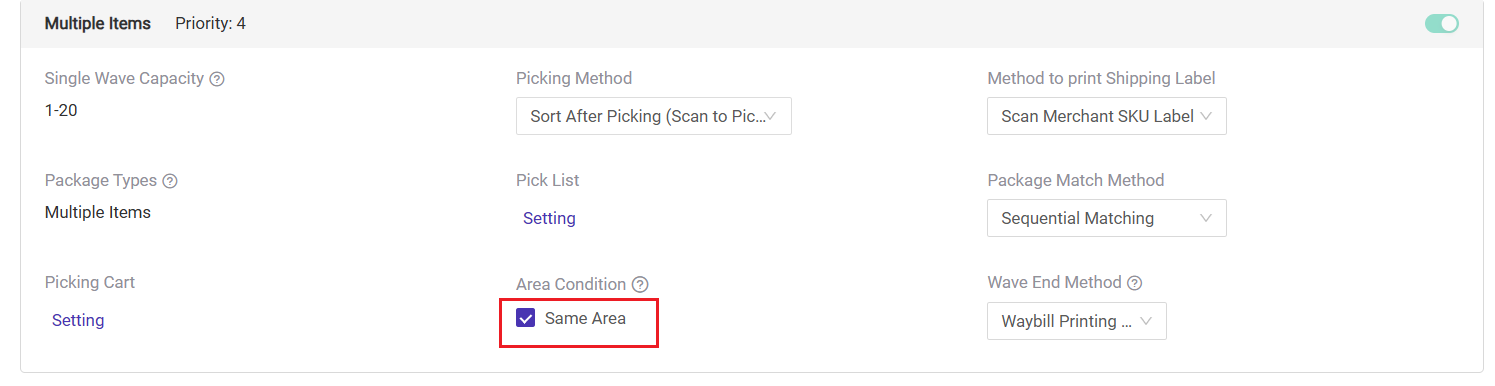

- If you have created warehouse area, you can enable this option to generate waves based on warehouse areas.

- Orders within the same area will be grouped into the same wave.

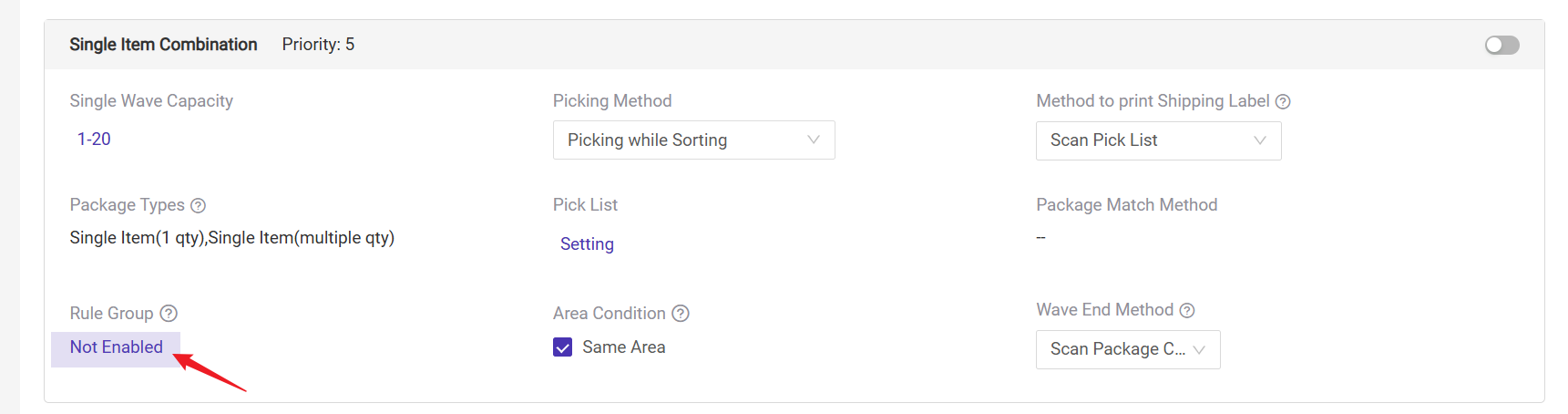

- The Rule Group feature automatically groups orders meeting specific conditions (such as SKU, weight, or category) into the same wave to improve picking and packing efficiency.

For more information, please visit the Introduction to Rule Group Feature — Generate Wave by Merchant SKU Group

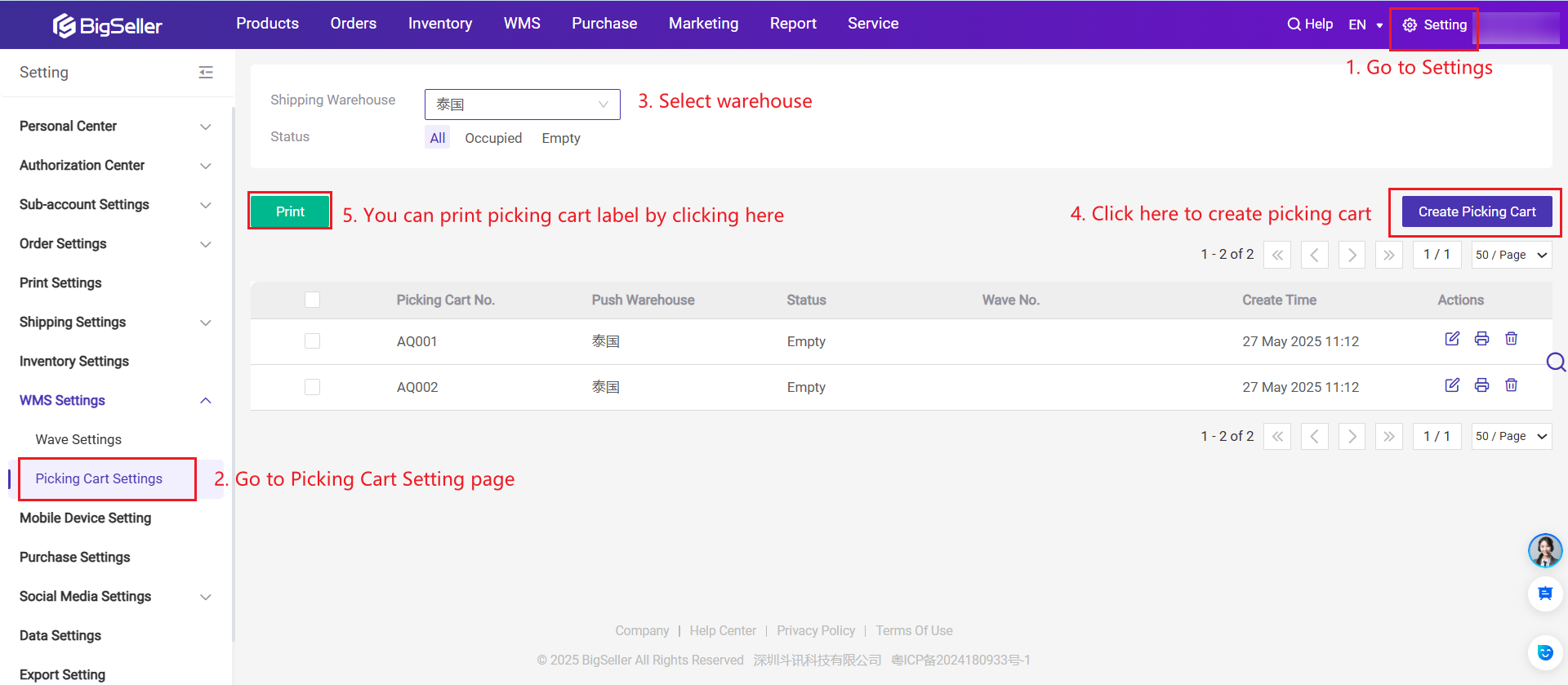

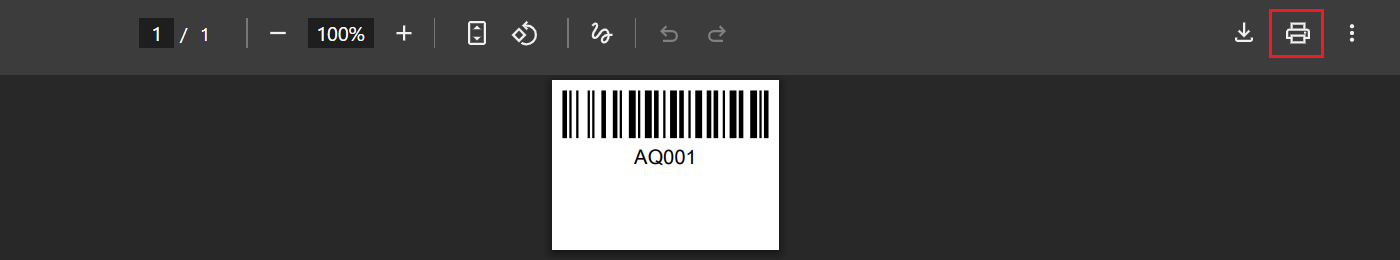

- If you are using the app for picking, you need to create a picking cart and print the cart label.

- Setup path: Wave Settings > Picking Cart Settings page.

💡 Notes

-

Any product in the package belongs to the selected SKUs, or

-

All products in the package belong to the selected SKUs.